Marine and Offshore

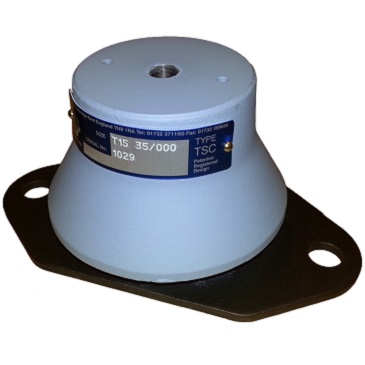

TSC - Combined Steel & Rubber Spring Unit Isolators Type TSC T20

A major advance in design has successfully combined the best characteristics of steel springs and rubber springs to produce an efficient, compact and economical range of unit isolators suitable for many types of applications. Many variants of these isolators, designed and manufactured by us have now been in service for more than twenty years. TSC unit isolators are highly effective in reducing the transmission of vibration, structure-borne noise and shock from a wide range of rotating and reciprocating machinery and in protecting sensitive apparatus from external disturbances. They are particularly suitable for marine and mobile applications as internal snubbers are incorporated to control movement of the isolated machine. Type approval by Det Norske Veritas and general type approval has been given by Lloyd’s Register of Shipping.

- Helical steel spring to BS1726 Class B.

- Inclined rubber springs are first grade natural rubber to metal bonded elements.

- SG iron castings to BS EN 1563 EN-GJS-400/15.

- Steel spring in most variants is isolated from the top casting by resilient seating pad reducing transmission of high frequency vibration and effectively damping spring coil surge resonance.

- Springs are pre-compressed on assembly

- resulting in high equivalent static deflection and load capacity with minimum change between loaded and unloaded height.

- Rubber spring elements are effectively protected by the top casting and its extended skirt.

- A selection of steel and rubber springs

- each having different vertical and lateral stiffness closely controlled in manufacture.

- Both types of spring support a proportion of the total load and thus the overall rate of creep is much reduced compared to an equivalent all-rubber unit isolator.

- Optional proof plates are available to enable removal of mountings for refurbishment (marine propulsion engines only).

- Optional soleplate is available to facilitate installation on resin chocks.

- Marine Propulsion Engines.

- Marine Generator Sets

- Fire Pumps

- All values of stiffness are nominal subject to ±15% variation on final assembly. The isolator rubber elements are pre-loaded 6 mm upon assembly.

- Stiffness is linear over working load range.

- Dynamic stiffness may vary with frequency. Values stated are reliable for calculation of low frequency characteristics below 100 Hz.

- Optimum system stiffness characteristics can be achieved by careful orientation of individual isolators.

- All connections to and from isolated machine must include flexible lengths, not only to prevent transmission of vibration through the connections and allow the system freedom of movement, but also to avoid possible failure of the connections.

- Analysis of the isolated system is normally undertaken by Christie & Grey to predict the response to ship motion, machine forces and shocks to enable the correct selection of flexible connections.

Case Study

Operator : Seabulk Towing Main Engines: 3 No. Caterpillar 3512C propulsion engines Christie & Grey Mountings: TSC T10 isolators Engine Operating Speed : 1200 rpm Calculated Vertical Isolation Efficiency : 96+ %

Read More